Lorem ipsum dolor sit amet, consectetur

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo. Nemo enim ipsam voluptatem quia voluptas sit a

Reference Fact Sheet

Project Description

Filtered water capacity 4,800 m³/d:1,680 m³/d (phase 1);additional 3,120 m³/d (phase 2)

Brownfield EPC

Modification of pre-treatment process steps, replacement of pressurized polymeric ultrafiltration

Location: South Africa

In operation since 01/2020

Process Chain

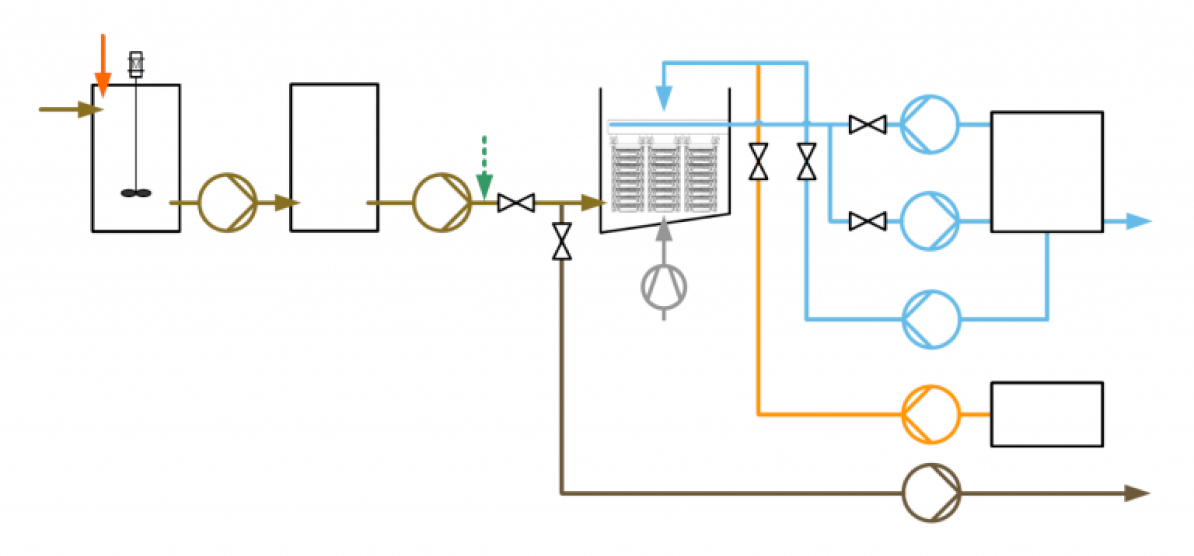

Lime dosage for precipitation of calcium and magnesium for hardness reduction (lime softening)

Blended feed water source from municipality and borehole

No settling of precipitants – direct transfer to filtration tanks

Activated carbon filters for dechlorination

UV system

Process Flow Diagram

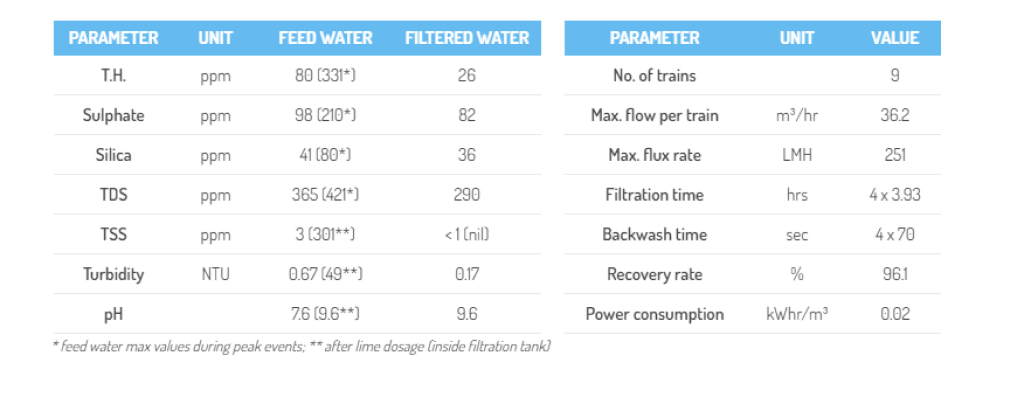

Performance Data

The feed water is a blend of municipal and borehole water. Both water streams have different properties. The overall blending ratio is dependent on water availability and quality. Sudden and strong peak events have led to the damage of the previously installed polymeric membrane system.

CERAFILTEC’s softening filtration process enables operation even with high varying water properties. A small amount of lime is currently being dosed to reach a pH of about 9.6 to reduce calcium hardness only. During peak events, lime is overdosed to reach a pH of about 10.5 to additionally reduce magnesium hardness. In this case, the pH is subsequently adjusted to about 9.6 prior to the ceramic filtration to ensure stable long-term operation.

Regardless of the total hardness level and lime dosing requirements, all precipitants are directly transferred to the ceramic flat sheet membrane without settling step in between.